Stamping foam

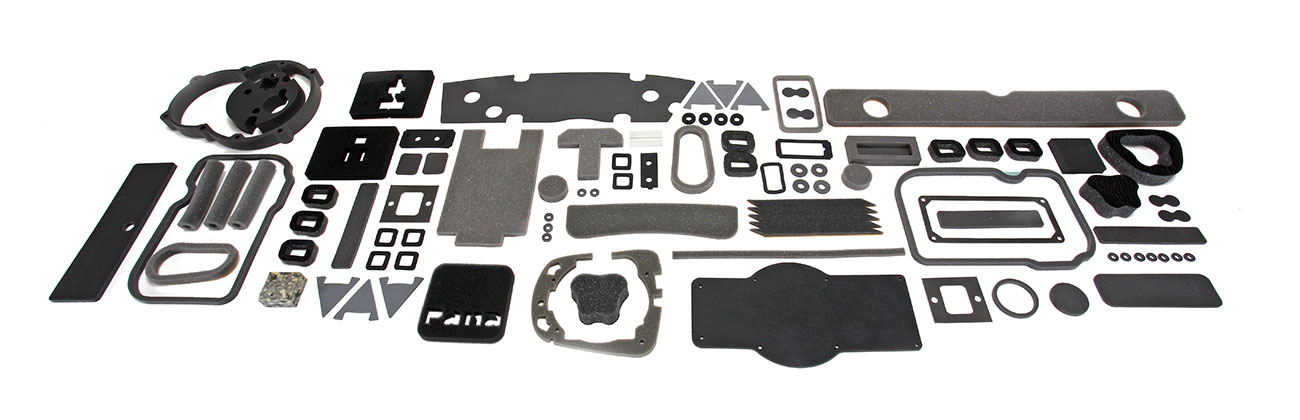

Hardly any other processing technique is as versatile as stamping. Foams are formed into the desired shape using die cutting tools that can be individually manufactured for each customer application. With our modern and diverse machinery, we have the possibility to produce even large quantities in a cost-effective way.

Our competences

Die-cut parts can be produced up to a size of 1,100 x 650 mm

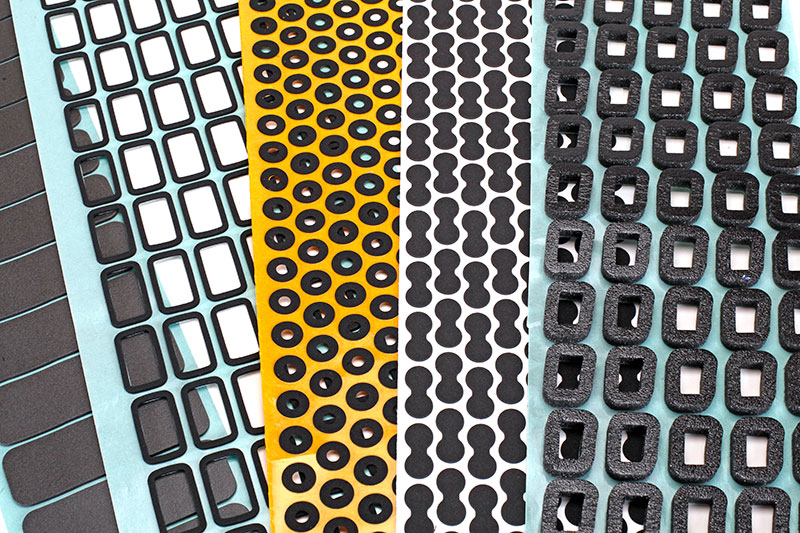

Individual and process-optimized formats for the customer: kiss-cut on sheets, kiss-cut on rolls, perforated on sheets or simply individual parts

Customer specific configuration of the parts for automated downstream processing

Rotary stamping

To meet the various requirements of our customers, self-adhesive gaskets, for example, can be die-cut in high volume, kiss-cut on roll with our rotary die-cutting machine. Rotary stamping is generally used for thin materials in mass production, while higher thicknesses can be concave. Stamping waste, such as inner parts or stamping mesh between parts, can be removed automatically in the downstream process on the machine.

Flatbed stamping

With our stamping systems, we can cover a wide variety of designs to suit the customer. We select the optimum part format to suit individual needs, for example kiss-cut on rolls, kiss-cut on sheets or individual parts. To make further processing as efficient as possible, we can remove excess material if requested.

"3 in 1" stamping machine

Our "3 in 1" die-cutting machine enables us to produce parts with a high degree of production complexity in an efficient and economical way. In this process, we are able to laminate the foam, stamp the parts, and perform the finishing (automatically remove the inner parts and wind up the finished rolls) on a single machine. In this way, we eliminate production steps on other equipment and can reduce lead times.

Frequently asked questions & answers about foam die cutting

Depending on the material, format and contour, thicker foams can also be die cut. However, foams can become "concave" during die-cutting; depending on the material thickness, this concavity varies.

We stamp self-adhesive foams using the kiss-cut method (foam punched down to the liner) on sheets or on rolls, as well as individually as loose parts. Perforated parts are also possible.

With our modern machinery we have the ability to produce almost any desired format adapted to the raw material.

Depending on the scope of the project, small batch sizes as well as large quantities with a high vertical range of manufacture can be offered cost-effectively.

All our foam die-cut parts are calculated on a project-specific basis. The costs for the required punching tools are only incurred once for the initial order.

Provided that the material is suitable and can be feasibly processed, it is possible to manufacture with customer material.