Laminating foam

You want to laminate your required foams with the most diverse materials? Our main expertise in laminating is in the area of "self-adhesive foams" - a composite material consisting of foam and double-sided adhesive tape. You can find an overview of our adhesives here.

Our competences

Single or double-sided foam finishing with a variety of double-sided adhesive tapes

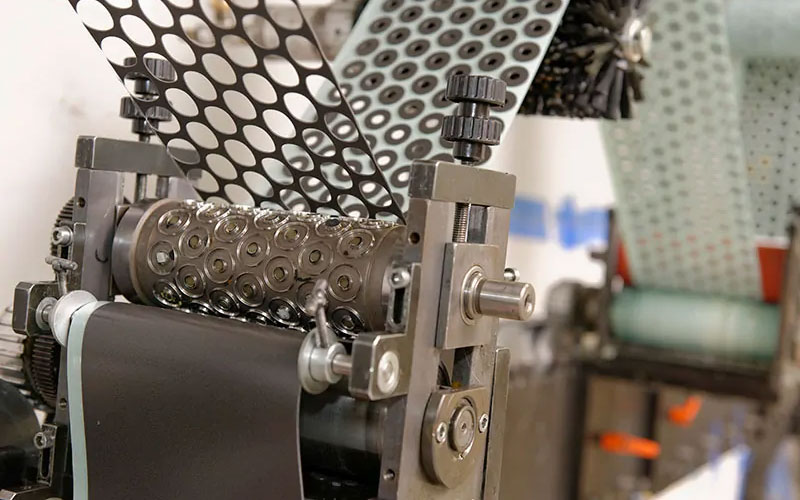

Excellent bonds between materials through heated pressure rollers

Individual roll lengths (depending on thickness and quality) and widths (up to 1,500 mm) possible

Other materials can also be laminated with our foams upon request

Foam lamination – Production process

Self-adhesive finishing

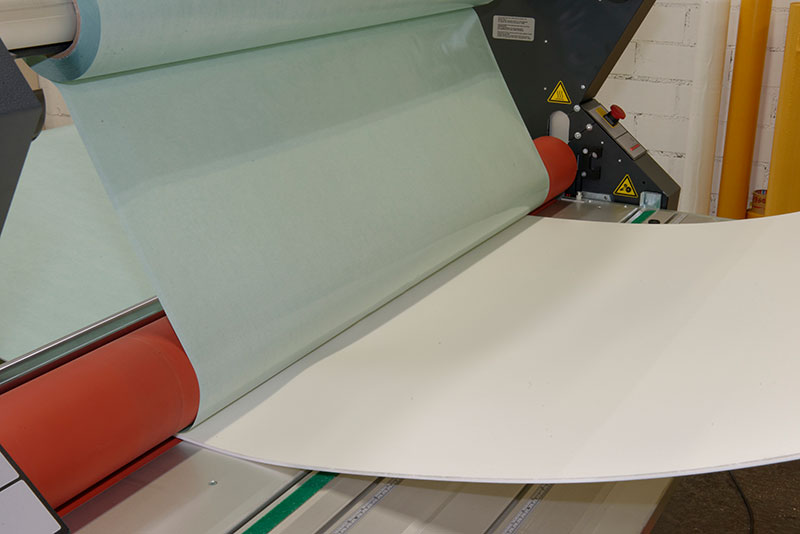

With our know-how and versatile laminating machines, we are able to equip sheets or rolls with a double-sided adhesive tape - on one or both sides.

With the help of heat and mechanical pressure, the material combinations are optimally bonded together.

Bespoke rolls made from foam sheets or rolls

By laminating them one after the other, sheets can also be used to produce rolls. Depending on the foam quality, material thickness and further processing customised roll lengths.

Additionally, rolls in custom lengths can be obtained by dedicated rewinding and cutting to length.

Laminating a wide range of materials

On request, we can combine special materials such as textile, velour or aluminium foil with our foam. It is also possible to combine two different foams.

Frequently asked questions & answers on the topic "Laminating foam"

In principle, we can equip any thickness with a double-sided adhesive tape.

The reason for this is that the heat liquefies the glue somewhat, which makes it adhere better to the foam. In combination with pressure, you get an excellent result.

We can provide each of our qualities with a double-sided adhesive tape.

The functionality must still be tested depending on the intended use!

All self-finished materials and composite parts created by bonding must be stored dry, in well-ventilated rooms and at as constant a temperature as possible of approx. +20°C.

When stored in this way, the products can be used for 6 to a maximum of 12 months.