Cutting foam

Thanks to our multiple cutting systems, we can cut our foams as simple quadratic shapes, as gaskets, or even geometric 2D shapes according to your requirements.

Our competences

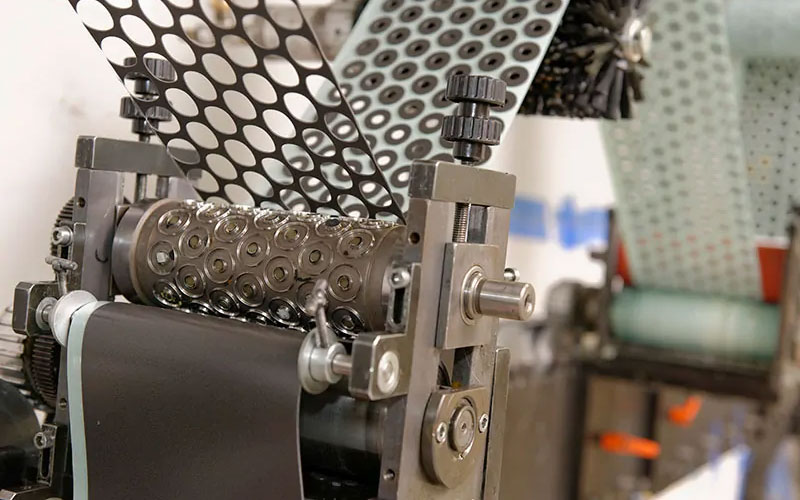

Slitting machine for gaskets from 3 mm wide

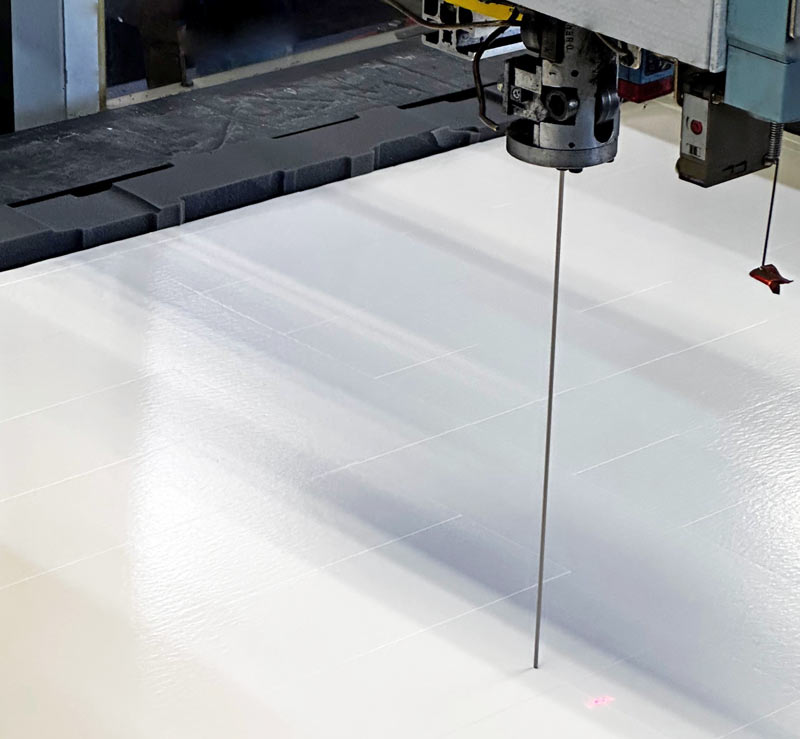

Waterjet cutting system for small series and prototypes

With our CNC controlled equipment we guarantee an optimal utilization of the material

Have foam cut to size - areas of application

Gaskets / Thin rolls

The production of narrow rolls is possible not only from rolls but also from sheets. With our equipment, we can offer widths as small as 3 mm.

The roll length can be customized according to the customer's wishes.

With our CNC-programmable water jet machine, which is also suitable for thicker materials, we can cut 2D forms. In contrast to stamping, this does not result in any concavities.

This manufacturing option is advantageous for small quantities, prototypes and pre-series samples, as no tooling costs are incurred.

Cuttings

We produce 2D shapes on our vertical cutting machines, using a cutting table or CNC-controlled automatic cutting machine. We are able to process sheet and roll material in various dimensions according to customer specifications.

Frequently asked questions & answers about foam cutting

Our foam qualities range from approx. 15 kg/m³ - 370 kg/m³. These can all be processed on our machines. Only the processing time varies depending on the density.

With our machinery we can cut foams by band blade, automatic cutting machine or by water jet, also as gaskets.

With our manufacturing capabilities, any foam with a self-adhesive finish on one or both sides can be cut to size.

We commonly work with PE foam, PUR foam and cellular rubber, but also with materials beyond our portfolio, which can also be cut to size after a positive feasibility study.