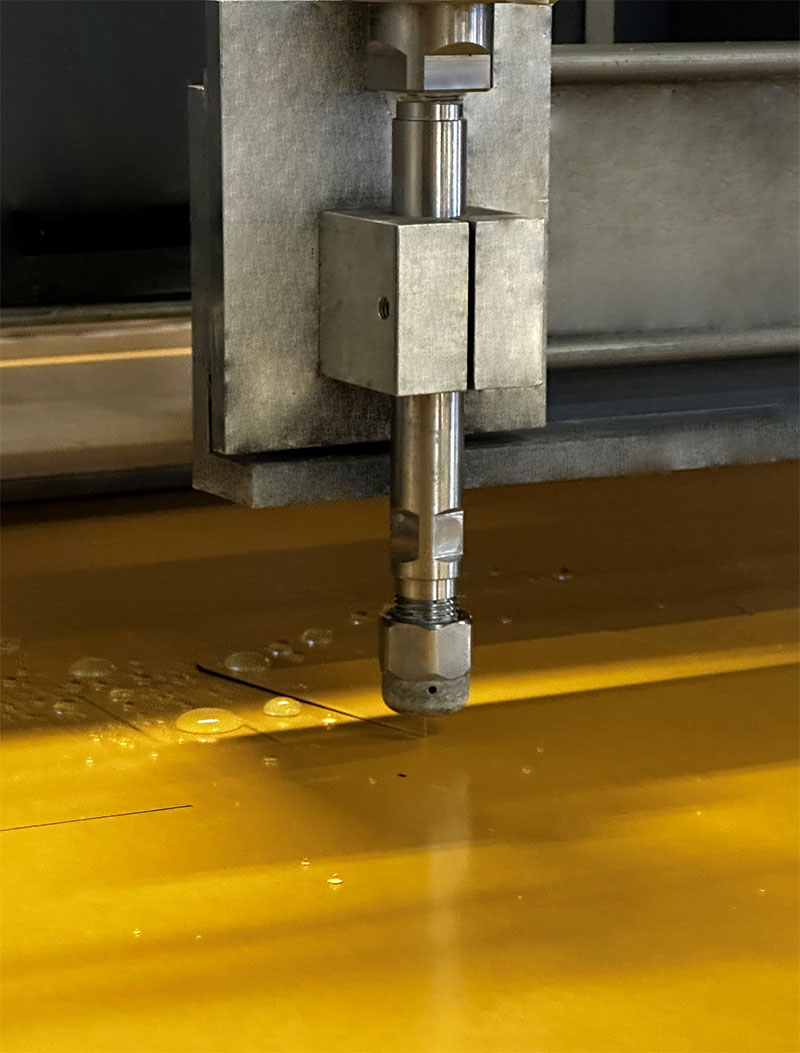

Water jet cutting of foams

With our CNC-programmable water jet machine, which is also suitable for thicker materials, we can cut 2D forms. In contrast to stamping, this does not result in any concavities.

This manufacturing option is advantageous for small quantities, prototypes and pre-series samples, as no tooling costs are incurred.

Frequently asked questions & answers about foam waterjet cutting

We generally process PE foam, PUR foam and cellular rubber, but also materials beyond our portfolio, which can also be cut on our waterjet system after a successful feasibility check.

Our foam qualities range from approx. 15kg/m³- 370kg/m³. These can all be processed on our machines. In addition to the volume weight, the strength of the qualities also plays a decisive role.

With our manufacturing capabilities, foams that are self-adhesive on one or both sides can also be cut with a waterjet.

In our portfolio, we only have soft pure waterjet cut. Accordingly, there is no addition of sand or other auxiliary materials.